With professional-grade face shields for health care providers running low, the University of Iowa’s medical device design business is using materials provided by Iowa manufacturers to build the coronavirus-fighting tools by the thousands.

The shields are from Iowa MADE, a university initiative that manufactures and markets simple, low-cost medical devices designed by faculty, staff, and students. This month, they started selling face shields that are in chronic short supply for health care providers who need them as protective equipment as they care for patients with COVID-19.

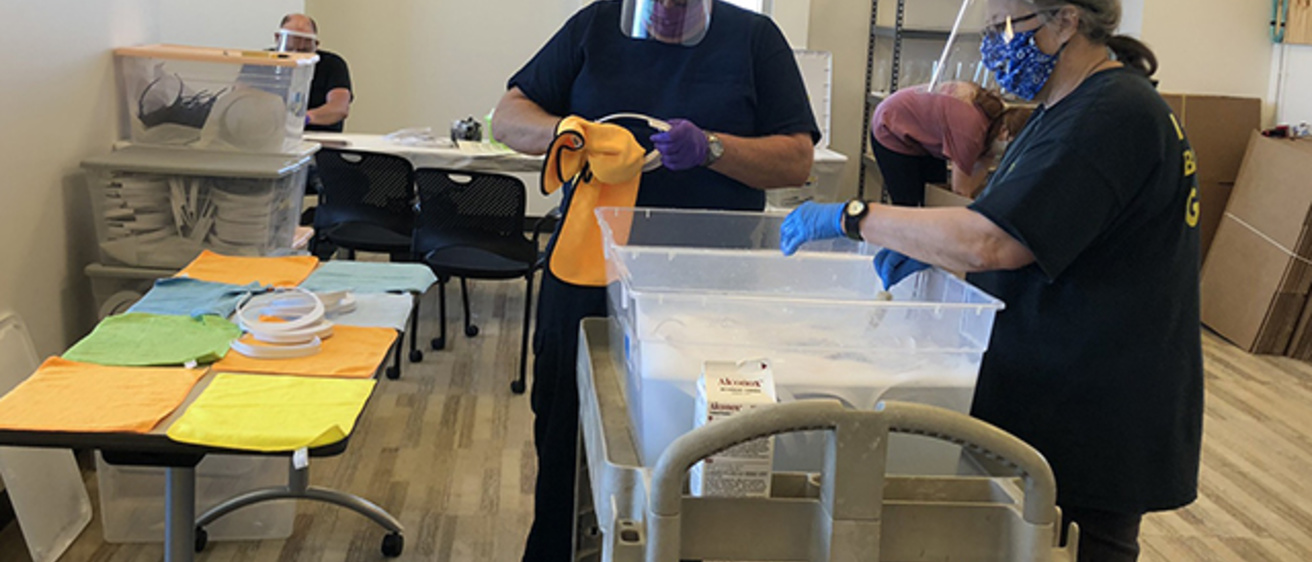

Jordan Kaufmann, executive director of Iowa MADE, says the shields are professional-grade and designed to last for some time. They use parts sourced from manufacturers around Iowa and are assembled by university staff members in the BioVentures Center on the Oakdale Campus in Coralville, Iowa.

“The face shields are lightweight and the halo that holds it to the user’s head is designed to be more comfortable for extended use,” Kaufmann says.

The shields are registered FDA-compliant Class I medical devices, as MADE adheres to the agency’s quality control protocols.

“Most important for us was meeting the FDA quality and safety standard,” says Jon Darsee, the university’s chief innovation officer, who along with Kaufmann has overseen the shield initiative.

The shields cost $7 each—enough to cover expenses—and are available on Iowa MADE’s website. Darsee says they have enough capacity to assemble up to 1,000 shields a day and have enough raw materials to manufacture between 80,000 and 100,000 shields.

Kaufmann says many of their customers so far have been vendors who are now required to wear protective equipment when they visit clients in hospitals. Those could include electricians, engineers, custodial services, industry representatives, or other contractors. She says nursing homes and care facilities are also buying them in significant numbers.

Darsee says that because of the urgency of filling shortages, the concept-to-market process that would normally take months was accelerated to less than five weeks. Early prototypes were made by Protostudios, the university’s 3-D printing operation that makes prototypes of innovative new products. Working with the Iowa Economic Development Authority, Darsee, Kaufmann, and Protostudios connected with manufacturers in Des Moines, Webster City, Cedar Rapids, and Grinnell to make the plastic shield, halo, foam padding, and other parts. The first orders were filled April 10.

The shields are cleaned, assembled, and packaged for delivery by 18 University of Iowa employees on temporary assignment from their regular university jobs, while the process is managed by three College of Engineering students working for MADE. Aside from filling a glaring market need, Darsee says the project gives those student employees real-world management experience helping to solve a critical challenge our community, state, and nation is facing.