When David Miles joined the physics and astronomy faculty at the University of Iowa in fall 2018, he was promised a furnace.

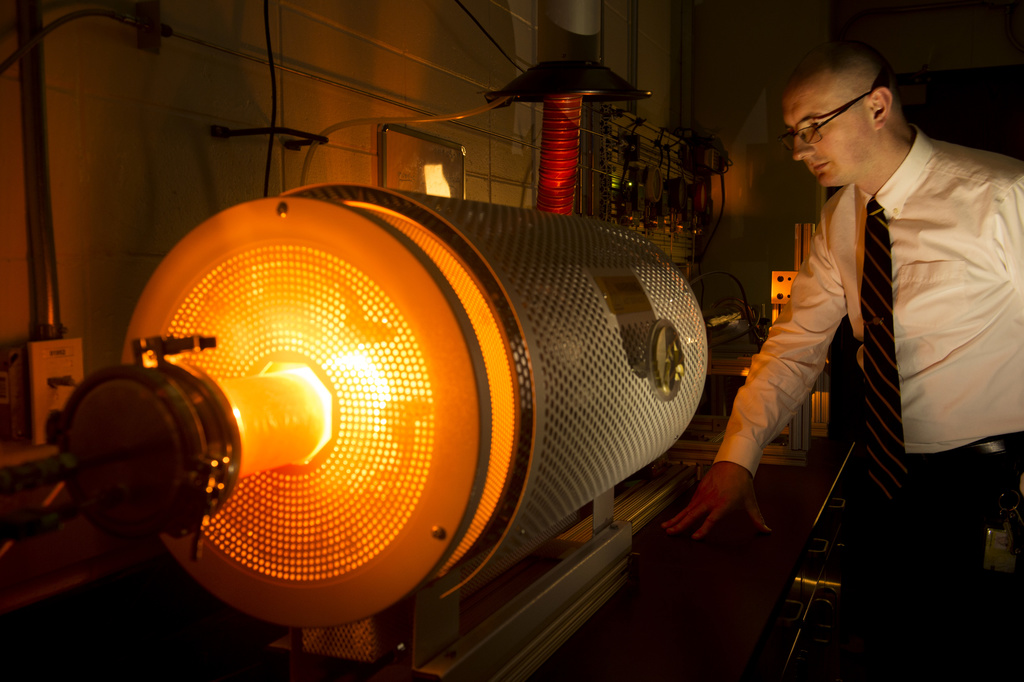

This wasn’t your typical heating device, however. The furnace in Miles’ lab, assembled this spring, can bake objects to more than 2,900 degrees Fahrenheit, far hotter than lava. And it is being used for a very specific purpose: to manufacture a critical space-instrument component for which there are almost no guidelines for production.

“We’re using the furnace to cook an essential piece of an instrument that has been lost to history,” Miles says.

What Iowa makes possible

Miles credits the Department of Physics and Astronomy and the College of Liberal Arts and Sciences with making funds available to him as a new faculty member to design and build the furnace. He says the funding clinched his decision to join the UI.

“To build fluxgate magnetometers, you need these cores,” he says. “I couldn’t have come here if I didn’t have the furnace and thus the ability to produce them. I am grateful to the university for its faith in me and my research.”

College of Liberal Arts and Sciences Interim Dean Joseph Kearney says startup funds are critical for giving new faculty the resources they need to succeed—and tailored for the arts, humanities, and sciences.

“Our goal is to jump-start their careers and allow them to successfully compete for highly competitive research funding to continue their work,” Kearney says.

That piece is a ring core, which is central to the functioning of a fluxgate magnetometer, an instrument used for measuring low-frequency magnetic fields. Fluxgate magnetometers have been part of space missions for decades, from the 1977 launch of the Voyager 1 spacecraft that has traveled farther from Earth than any other human-made object to the new-generation missions using satellites the size of a loaf of bread to study various phenomena of Earth and space.

“Fluxgate magnetometers are one of the workhorse instruments in space science missions,” Miles says.

The UI is one of only a handful of academic institutions worldwide with a furnace capable of producing ring cores.

“We are positioning the UI to provide an essential instrument on future science space missions and to further science using fleets of smaller spacecraft,” Miles says.

Moreover, the furnace and the research associated with it is a major reason why Miles and Associate Research Scientist George Hospodarsky recently won a $1 million grant from NASA to build a new type of compact magnetometer.

Ring cores are needed to detect external magnetic fields around Earth and in space. The goal, Miles says, is to squelch any magnetic energy emanating from the magnetometer itself, thereby making the instrument even more capable of sensing low-frequency magnetic waves around it.

“There’s a whole lot of interest in making low-noise cores, which is basically engineering that little piece of metal to have very low intrinsic magnetic noise so that it doesn’t corrupt the measurements we’re taking of the Earth’s magnetic field,” Miles says.

But there’s a major catch: No one is exactly sure how to make them, and with good reason. Ring cores originally were produced in the 1960s for the U.S. Navy, which used them to detect magnetic fields from otherwise “invisible” enemy submarines (such as those featured in the movie, The Hunt for Red October) and to guide torpedoes toward those subs.

The manufacturing process for the ring cores was kept classified, and production is believed to have been limited to a single company—Infinetics, Inc. When Infinetics went out of business in the 1990s, it took much of its ring-core manufacturing information to its corporate grave.

Since then, space scientists have used a finite inventory of rings that is shrinking with each new mission. Now there’s an opportunity to build a better ring core, and that’s what Miles and his team hope to do.

In a lab on the first floor of Van Allen Hall, Miles and his team mix high-purity metal powders and melt them in the furnace at a temperature of 2,900 degrees Fahrenheit. The product is a metal slug “mixed in a ratio that is, for a lack of a better word, ‘magic,’” Miles says.

The researchers use jeweler’s tools to roll the metal slug into ultra-thin sheets that are wound onto a bobbin, forming the heart of the instrument’s magnetic-detecting capabilities. The group is close to producing a ring core with the magnetic quietude of the 1960s-era ring cores; once that is accomplished, they aim to further refine the process.

“This is an opportunity to build a better ring core,” Miles says.

In a final step, the ring-core assembly is connected to sensors and a small electronics board, becoming a fluxgate magnetometer.

Joshua Larson, a UI senior majoring in physics and electrical engineering, has been helping build and test fluxgate magnetometers manufactured in Miles’ lab with the goal of creating a prototype that can be used for a planned fleet of miniature satellites to study Earth and space weather. Last month, Larson took a prototype fluxgate magnetometer to the Laboratory for Atmospheric and Space Physics at the University of Colorado Boulder to make sure it meshes with the rest of the satellite.

“This research has put to the test some of the things that I have learned in both engineering and physics, in sort of extreme ways,” says Larson, from Mount Pleasant, Iowa, the same hometown as UI space pioneer James Van Allen. “I’ve learned a lot about how to build and test instrument prototypes, and it’s helped me to hone the skills further than I would have been able to do in a classroom.”

Suman Sherwani, a senior electrical and computer engineering major from Naperville, Illinois, worked on the electronics for a magnetometer simulator that she and others tested in Norway in April.

Sherwani credits her research experience as an undergraduate student with broadening her academic and potential career interests.

“I thought that I would go straight into industry after graduation in December, but since I’ve started working with Dr. Miles, I have started looking into graduate programs in the field,” Sherwani says. “I still haven't decided what I’m going to do, but it has given me a lot to think about. This is what I’d love to do for the rest of my life.”