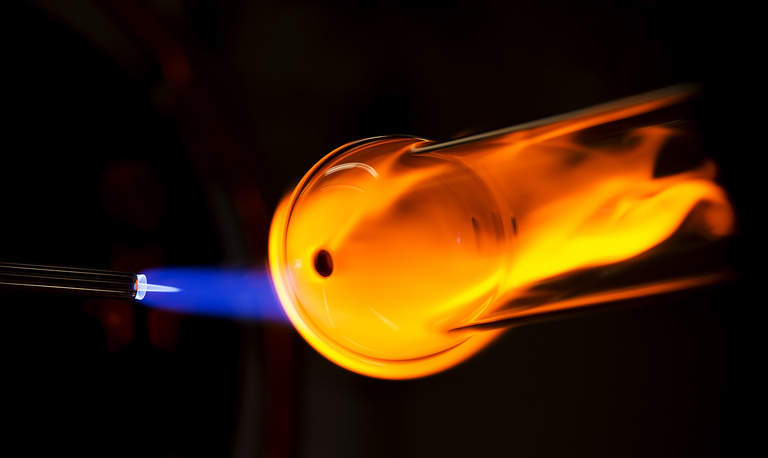

In a room stocked with glass of all shapes and sizes, Benjamin Revis creates objects of beauty and purpose.

Revis is an artist, but not in the traditional sense. As the University of Iowa’s professional scientific glassblower, he custom designs and repairs glass equipment for students and faculty across campus.

In five years at the UI, Revis has worked on more than 2,000 pieces of glassware. Although some items can be machine molded, most pieces must be assembled manually.

“Often, people take for granted how technical and challenging scientific glassblowing is. The craft is a lot more than just making beakers and test tubes,” says Revis, one of just two professional scientific glassblowers in the state of Iowa.

Video by Clarity Guerra.

Revis’ shop is located in the Chemistry Building, but he performs work across the university. His clients have included the ophthalmology, biomedical engineering, geological sciences, physics and astronomy, and visual arts departments. He gets especially excited about novel jobs, like the time UI 3-D designer Monica Correia asked him to produce a custom glass insert to fit into a series of wooden vases that she's creating for the 100% Design show taking place in London this September. The insert will allow her to place live flowers in the vases without damaging the wood.

“Having a scientific glassblower on campus is very convenient. I can visit the shop anytime and talk with (Revis) about the piece and any modifications needed,” says Correia, associate professor in the UI School of Art and Art History. “It is also more cost effective. He has the capability to make custom pieces, something that would be much more expensive if I contacted an outside glass manufacturer.”

Revis stumbled across his trade by accident. He was a senior at Purdue University when he saw an artistic glassblowing demo while perusing a local church carnival.

“I remember being mesmerized,” he says. “I couldn’t pull myself away and ended up watching the glassblower for over two hours.”

Later in his senior year, Revis enrolled in a scientific glassblowing class. Although he graduated with a degree in electrical engineering, he stayed at Purdue for two more years to receive on-the-job training in the glass shop.

And though he got a nuclear engineering job—senior reactor operator—at Purdue, Revis’ passion for glassblowing never waned. When an opportunity to return to the profession arose, Revis moved to Iowa to succeed Pete Hatch, who had been the UI’s scientific glassblower for 34 years.

A lot of Revis’ work consists of repairs, but even those can be tricky. For instance, “a crack is either going to worsen or get better,” he says. “Each one is a little different.”

Even if he cannot repair the crack, Revis can control the way the glass breaks. This technique allows scientists to recover the product inside and continue with the experiments as Revis assesses and repairs the damage.

From repairs to custom pieces, Revis pushes himself to learn something new from each project.

“The truth is there is still so much to be learned,” he says. “I continue to grow with each new job request and challenge myself to improve every day.”

The glass shop, located in W152 CB, is open from 8 a.m. to 4:30 p.m. Monday through Thursday and 8 a.m. to noon on Fridays.

Some fun facts about glassblowing

-

The UI has had nine scientific glassblowers in the past 94 years.

-

Revis teaches a class called Scientific Glassblowing Fundamentals in the winter session; it's open to all UI students.

-

Revis also teaches artistic glassblowing classes at Beadology.

-

The earliest recorded use of glass was by the Egyptians, who used it to glaze tiles, make figures, and create the earliest-known glass beads.

-

In the past, it was very common for chemists to perform their own glassblowing.

-

PYREX was developed to prevent railroad lantern lenses from breaking during rainstorms.