Many students use cell phones and other electronic devices every day, but few students understand how the devices are made and how they work.

For that reason and others, the University of Iowa Microfabrication Facility (UIMF), part of the Optical Science and Technology Center located in the Iowa Advanced Technologies Laboratory building, has established a course on the subject.

Called "Fundamentals of Micro and Nanofabrication" and offered in collaboration with the Department of Physics and Astronomy, the course is designed to serve undergraduate and graduate students. Students of any science, engineering, or medical discipline with at least some lab experience are invited to enroll in the course.

Facility director Aju Jugessur says, "Students obtain hands-on experience on the state-of-the-art nano-tools in the facility and it prepares them for a multidisciplinary education that is a key requirement in the training of the next generation of scientists, engineers, and technologists."

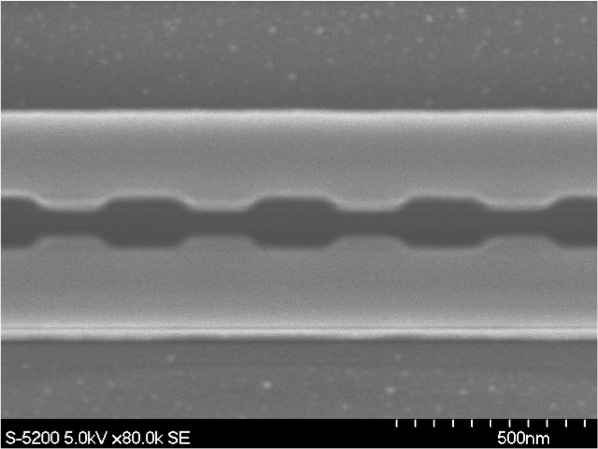

By way of comparison, a human hair is about 100,000 nanometers wide, while UIMF researchers can make components at least 10,000 times smaller. He notes that the Apple iPhone 5s has an A7 chip with a 28-nanometer process, meaning the smallest feature in the device measures 28 nanometers. Also, "technologies of the small” have long at work in nature, where living organisms are formed atom by atom—a process that inspires technology.

Jugessur says that there will be a need for some two million micro and nanofabrication high-tech workers in North America by 2025, and that students need skills in this emerging area. The skills acquired are also easily transferable from one high-tech sector to another, providing the students with a wide range of career choices. He adds that UIMF is enabling research areas that will help solve worker shortages in areas such as medicine, energy, communications, astronomy, computing, and the environment while improving the lives of Iowans and others.

Jugessur says the UIMF state-of-the-art nanotechnology clean-room is equipped with a wide range of tools for device fabrication and measurements for cutting-edge research in areas ranging from light-emitting diodes and solar cells to bio-chips and medical implants. As a core facility and service center, UIMF specializes in micro and nano manufacturing technologies while serving several academic departments on campus and private companies.

The UIMF unites many disciplines since the Departments of Physics and Astronomy, Chemistry, Electrical Engineering, Chemical and Bio-Chemical Engineering use the facility and, potentially, several medical departments, as well. Research areas and development of technologies enabled by this facility ranges from bio-chips for medical diagnostics, nano-scale sensors for the detection of environmental and biological pathogens to X-ray imaging, solar cells, optical devices and light-emitting diodes. As such, the facility aspires to serve as a common platform for researchers with different academic backgrounds to meet, discuss, and generate multi-disciplinary research ideas and grant proposals.

The growth possibilities in the fields of nanoscale science and engineering and nanofabrication are almost limitless, he says.

As Nobel laureate Richard Feynman noted almost 50 years ago, “When we get to the very, very small world—say circuits of seven atoms, we have a lot of new things that would happen that represent completely new opportunities for design.” The University of Iowa Microfabrication Facility, Optical Science and Technology Center will help the UI explore those opportunities.

For more information, visit the UIMF website.